Bramble Energy – Clean Air Day: bramble energy urges greater investment in hydrogen technology to combat dangerous levels of air pollution

- Bramble Energy advocates Clean Air Day initiative and the need to decarbonise transportation quickly

- Crawley-based company is vocal in the potential hydrogen plays for cleaner transportation

- Air pollution is a rising crisis that contributes to adverse mental and physical health

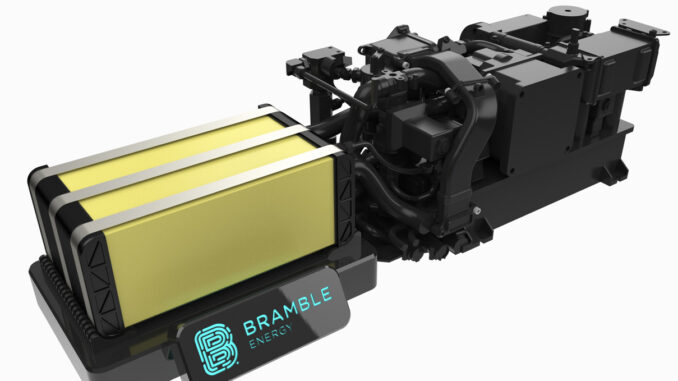

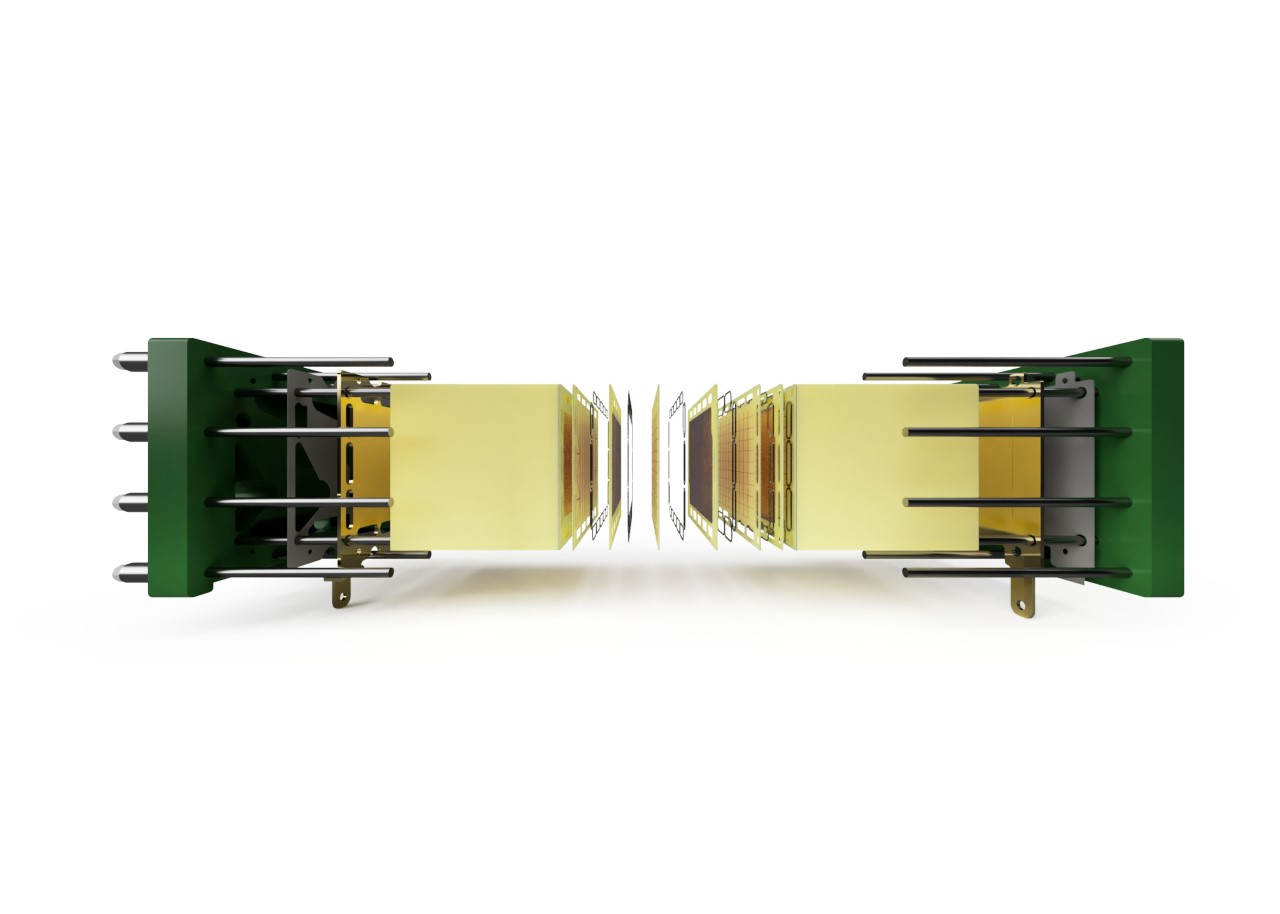

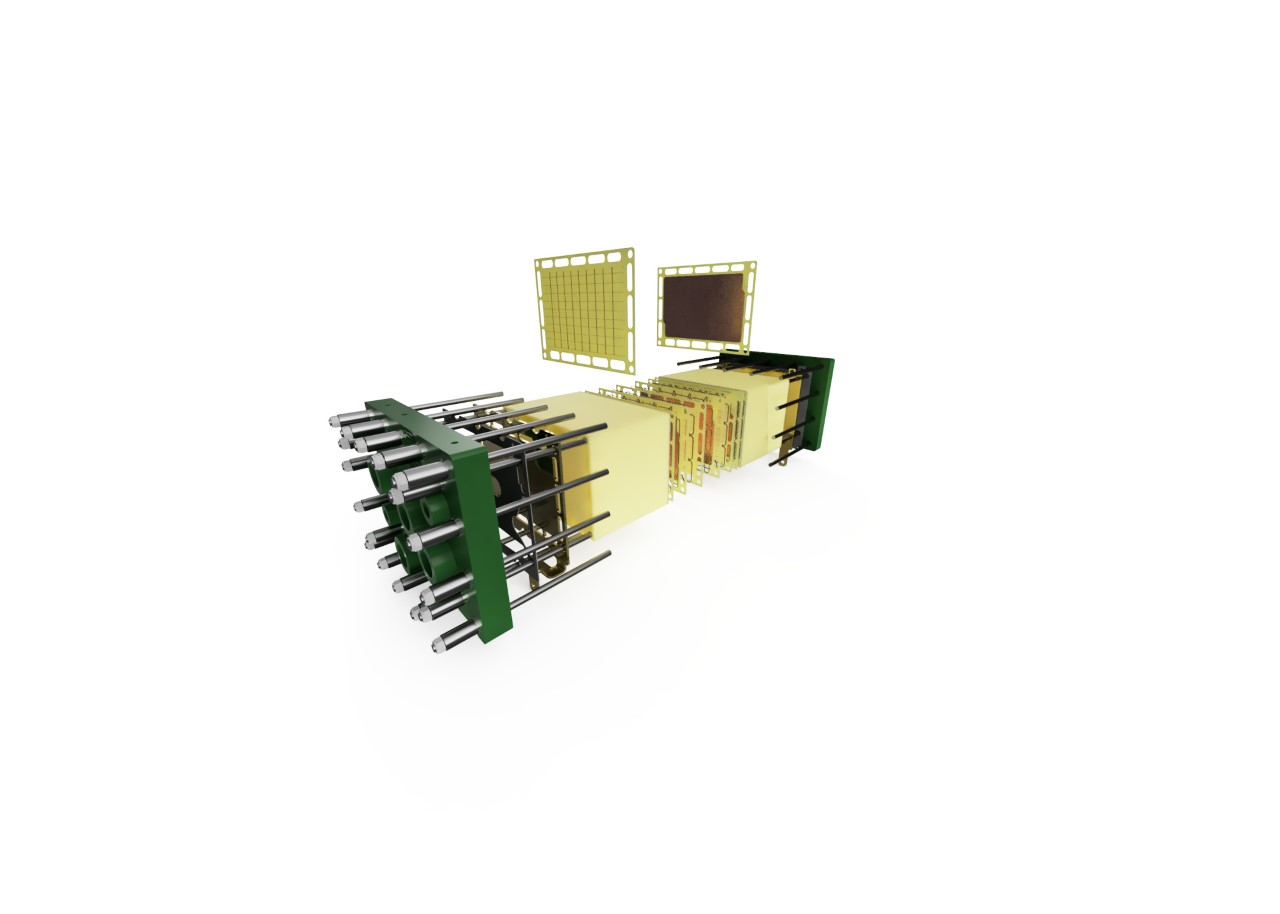

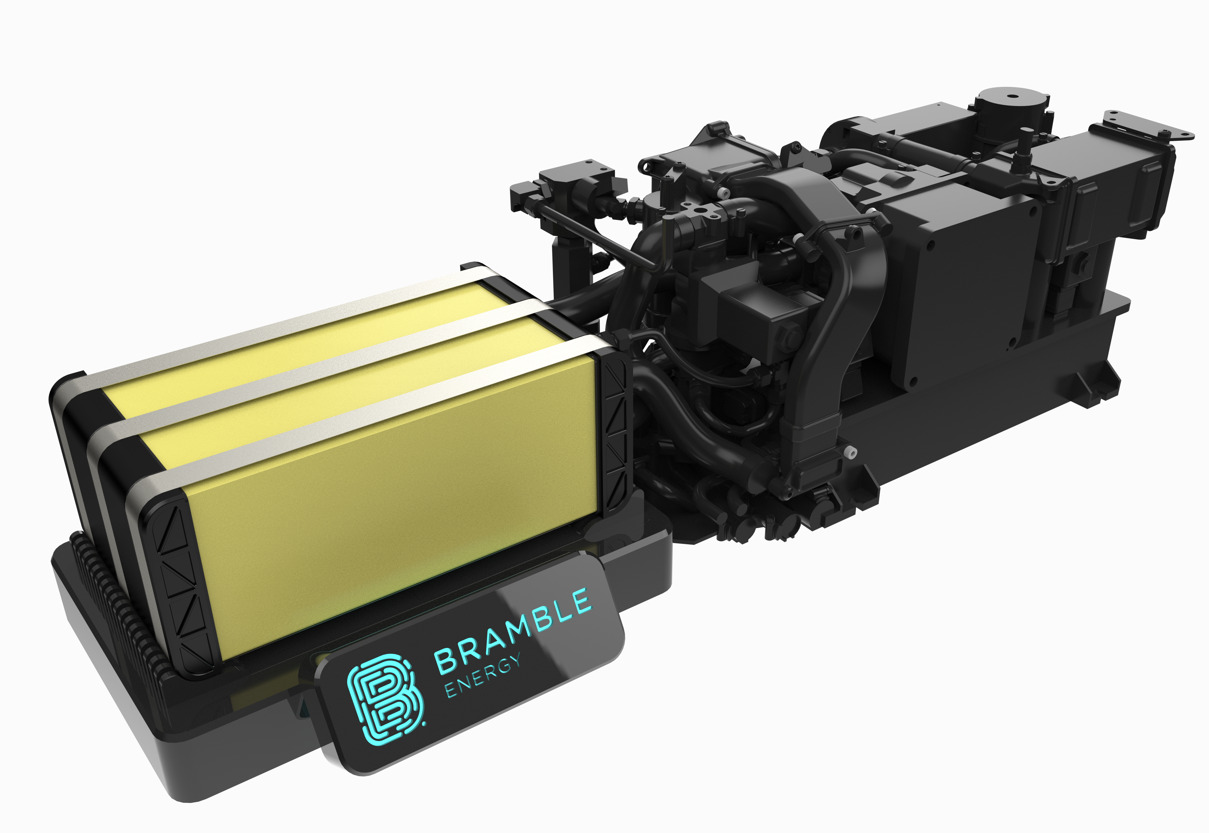

- Bramble Energy has developed the world’s first printed circuit board fuel cell (PCBFCTM) stack technology

- Revolutionary technology provides a viable route for hydrogen as they can be manufactured in almost any size or arrangement at much greater speed and scale than traditional electrochemical stacks, at a much lower cost

Bramble Energy

Bramble Energy, a leading innovator in fuel cell technology, is proud to announce its strong support for Clean Air Day as it raises awareness for the urgent need for cleaner air and promotes sustainable transportation solutions.

Clean Air Day serves as a poignant reminder of the environmental and health challenges posed by air pollution, one of the most significant environmental threats to public health. The initiative raises awareness of the need to address this pressing issue and prioritise sustainable transportation alternatives.

Bramble Energy recognises the dangerous impact air pollution can have on physical wellbeing and mental health, and is calling for industry to take action in accelerating its uptake of hydrogen as a viable clean and zero-emission solution for transportation

The potential for hydrogen as a clean solution in a wide range of mobility industries is immense. Hydrogen vehicles emit just water vapour and have the unique ability to clean the air as they drive, further reducing emissions and improving air quality.

With an urgent need to decarbonise the high-polluting transportation sector as quickly as possible, hydrogen, especially when produced from renewable sources (Green Hydrogen), represents an alternative, sustainable route for transportation to pivot away from fossil fuelled vehicles without relying solely on battery electrification.

BEVs not the only answer

Dr Tom Mason, CEO of Bramble Energy, said: “Meeting net-zero targets requires a multi-energy approach across industries. While batteries will continue to improve, BEVs are not a singular, silver bullet, solution. Bramble Energy’s innovative PCBFC™ technology provides a cost-effective pathway for transport operators to transition to hydrogen without high initial investments.

“We’re committed to making hydrogen fuel cells more accessible to a wide range of industries and businesses using our PCB technology, driving us closer to the goal of achieving net-zero emissions. Hydrogen will become a major part of the zero-emission solution over the next decade but it needs the support and vision to make this reality as quickly as possible.”

With its revolutionary world’s first Printed Circuit Board (PCB) fuel cell technology (PCBFC™), Bramble Energy is poised to accelerate the transition to hydrogen mobility and contribute to a healthier and more sustainable future.

The patent protected PCBFC™ technology revolutionises the manufacturing process of fuel cells by leveraging the innovative use of Printed Circuit Boards (PCBs), a common component found in electronic products. This offers unprecedented efficiency benefits over traditional fuel cell manufacturing methods, enabling cost-effective, scalable, and rapid production of fuel cells for various applications.

Reduced manufacturing costs

Bramble Energy’s PCBFC™ digitally tooled manufacturing process reduces costs and turnaround times, which are two of the biggest barriers to hydrogen adoption, providing design, manufacture, testing, and shipping of a PCBFC™ in a matter of weeks, enabling faster deployment of hydrogen solutions.

Thanks to its lower material, production, and manufacturing costs at the stack level, Bramble Energy’s PCBFC™ technology is two to three times cheaper compared to traditional fuel cell stacks. This affordability factor, coupled with its flexibility in manufacturing and business models, makes the option of hydrogen fuel cells more accessible for a wide range of industries and businesses, driving the transition to a net-zero future.

Bramble Energy Hydrogen Fuel Cell Technologies

There is a growing interest for hydrogen solutions at a government level, with projects receiving substantial support and funding initiatives. The recent allocation of £77m from the Advanced Propulsion Centre for hydrogen projects saw Bramble Energy awarded £6.3m for its lead role in the Hydrogen Electric Integrated Drivetrain Initiative (HEIDI) project where it will develop a hydrogen-powered double-deck bus, using its first-of-its-kind Printed Circuit Board (PCB) fuel cell technology.

Bramble Energy urges industry decision makers, from haulage, freight, to bus and coach fleet operators to be increasing investments in hydrogen fuel cell technologies to develop and deliver solutions that meet the growing demand for sustainable transportation.

With its potential to revolutionise the fuel cell market, Bramble Energy’s PCBFC™ technology paves the way for the widespread adoption of hydrogen in automotive, marine, and energy storage applications. By making hydrogen fuel cells more affordable and accessible, Bramble Energy is actively contributing to the realisation of a cleaner, greener, and more sustainable future.

Be the first to comment